EC150 Extrusion System |

|

| • | Detect waving or running edges, gaps, and torn edges quickly and automatically |

| • | Insure proper web temperatures for strong film-to-substrate adhesion |

| • | Improve profitability and product quality Automate quality monitoring |

| • | Reduce scrap |

Product Description

The EC150 Thermal Imaging System is an automated surface inspection system for detecting, measuring, and classifying defects occurring in extrusion coating, co-extrusion and laminating processes. This system provides a unique capability for managing the quality of plastic film extrusion processes.

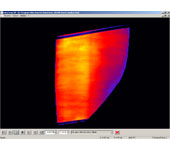

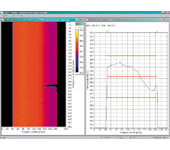

Temperature and viscosity variations in the local melt streams across the width of an extruder flow channel can cause "wavy"; or "running" edges, gaps, and edge-tears in the extruded film. Using the MP150 Process Imager, the EC150 System continuously monitors the temperature distribution and width of the extruded melt curtain to automatically detect such imperfections.

The EC150 system continuously monitors the extrusion process allowing temperature data to be visualized as a line graph (profile) and a thermographic image. Profiles and images may be printed or archived for future analysis.

Ms Liên

Ms Liên